Kanban Method

Benefits

- Easy implementation and adaptation.

- Productivity increase by up to 30 %.

- Greater flexibility and adaptation to changes.

- Transparency and continuous workflow.

- Instability in the amount of work.

- Monitoring and compliance of activities.

- Little disruptive and orderly.

- Scalation in multiple teams.

Introduction to Kanban

- Born from the Toyota Production Model.

- Kanban means “card you can see”.

- Involves the use of visual aid to follow up on production.

- This process was observed in the 50s in the grocery stores (JIT).

- The use of visual aid is effective and has become a common practice.

- A Kanban board helps the team increase its effectiveness.

- Adopted as an “Agile practice” in the early 2000s.

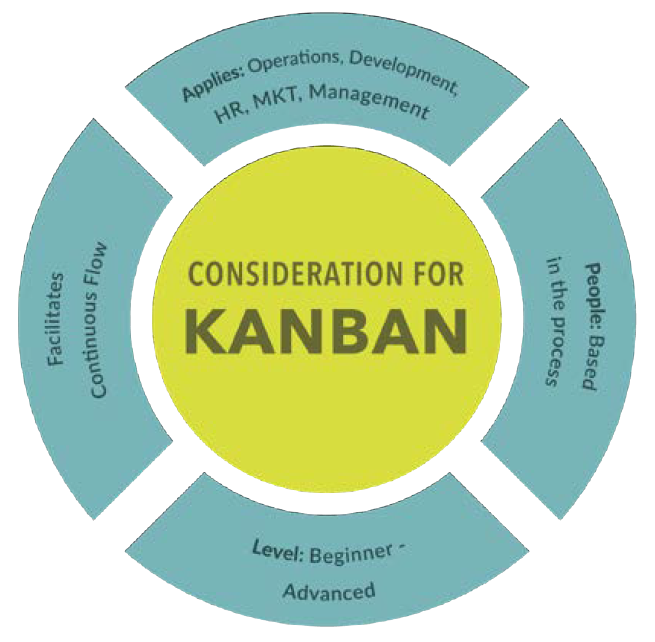

Kanban Application

It is better used when the team needs the following conditions:

- Flexibility.

- Focus on continuous delivery.

- Increase in productivity and quality.

- Greater efficiency.

- Focus on team members.

- Variability in the workload.

- Waste reduction.

- Respect current processes.

Wrong Reasons

- It seems easier, simpler, friendlier.

- You don’t need to change anything… Like Scrum.

- Scrum implementation failed.

- Where do I need to defragment the problems?

Basic Properties

- Visualize the workflow.

- Limit work in process.

- Manage the flow.

- Define the process.

- Make the process policies very explicit.

- Implement feedback cycles.

- Improve collaboratively.

Última modificación: miércoles, 6 de abril de 2022, 15:37